Flammable Liquids Filling Line

FILLING SYSTEMS APPLICATIONS

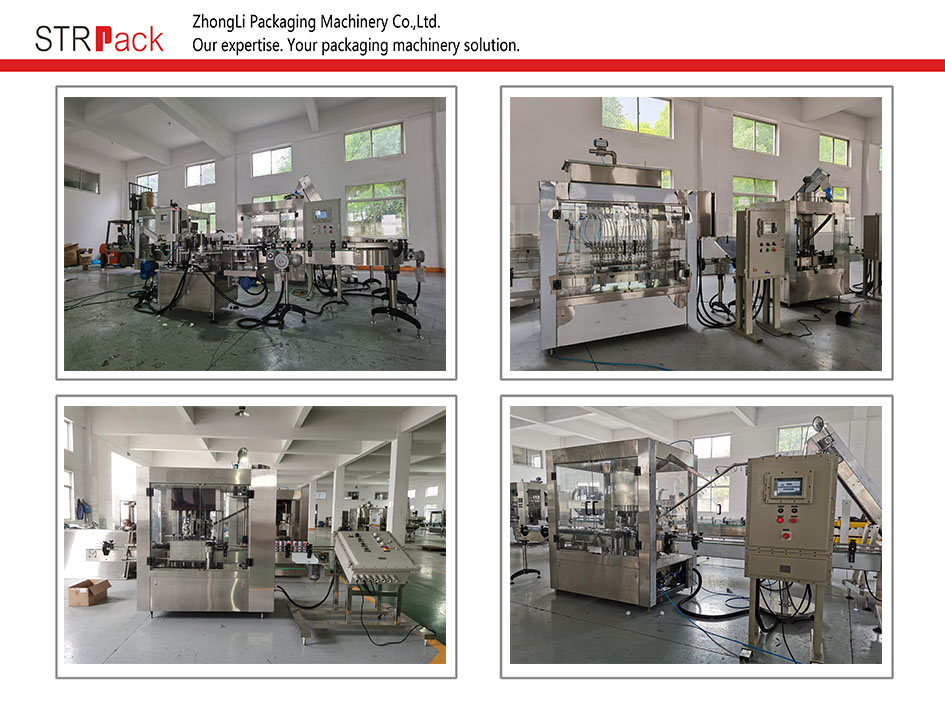

Intrinsically Safe (Explosion Proof) Filling Machines

Filling Machines For Flammable Liquids

It can be easy to overlook the fact that even hazardous chemicals and flammable products must be prepared for the end user by getting those liquids into the proper containers. Of course, packaging flammable liquids presents some unique challenges to packaging machinery manufacturers. While each packaging project will be handled based on the unique characteristics of the package, product and process itself, there are generally two common ways to package flammable liquids using an semi-automatic or automatic filling machines.

- Intrinsically Safe (Explosion Proof) Filling Line

- Fills wide range of product sizes: 100ml - 1000ml

- Bottles Per Minute: 30-120 (depending on size and product viscosity)

Machines Included:

Automatic Explosion Proof Filling Machine For Flammable Liquids

Automatic Explosion Proof Capping Machine

Filling Machines For Flammable Liquids

Our explosion proof lines feature machines from all categories: both semi and fully automatic, both volumetric and net weight, and both pneumatically and electronically controlled.

PNEUMATIC CONSTRUCTION

ELECTRONIC CONTROLS WITH INTRINSICALLY SAFE CONSTRUCTION

In other cases, where pneuamatically controlled machinery simply may not meet the needs of the packager, electronic controls will still be used, but special steps will be taken in the construction of the equipment to protect against the likelihood of a spark or arc from those controls. The machine itself will be constructed as an intrinsically safe liquid filler. In basic terms, PLC's, sensors or any other circuit on this type of machine will be enclosed to ensure that sparks, arcs or other effects are incapable of igniting the flammable liquids being packaged. Explosion-proof filling machines may also use a purge or pressurization for certain enclosures where fumes or vapors may also ignite.

While different filling principles, various options and different levels of automation are all available when filling flammable liquids, pneumatic or intrinsically safe construction is always a must. The construction of such equipment protects not only the machinery itself but also those working in and around the machinery. In addition, the added protection seldom takes away from the performance, reliability or efficiency of the machinery, making it a positive solution for the packager, machine operators and consumers alike.

STRPACK Specializes in manufacturing a full range of quality filling systems for bottle filling in a diverse group of industries. Our experienced sales and engineering teams understand the specialized needs of these industries and will work with you to develop a solution that will work for you.

BOTTLE FILLER OPTIONS

STRPACK Filling Line can be manufactured in an array of configurations to suit your application. These configurations can also be combined so as to be very specific to your needs.

Our bottle fillers range from entry-level table top units to fully automated filling systems. Our custom filling equipment can be tailored for industries such as:

Acids & Corrosives Liquid Filling Line

Liquid Soap & Hand Sanitizer Filling Line

Janitorial and Household Cleaning Products Filling Capping Packaging Line

Personal care, Health, and Beauty Filling Packaging Line

Lubricant Engine Oil Filling Capping Labeling & Carton Packing Line

Pharmaceutical and Nutraceutical Filling Line

Flammable Liquids Filling Line

--Focusing on Development, Packaging Industry Leader

--Keeping on Recruiting Talents and Innovation

--Advanced equipment, Guaranteed quality

For quick response please contact us by cellphone/WhatsApp:008617317720909