Automatic Piston Type Sauce Filling Machine

Oils, Soups, Sauces, Seasonings & Dressings Filling Solutions

Brief Introduction:

Our Sauce Filling Machine — from granular filling machines to bottle filling machines — can deposit pumpable or free-flowing foods into a variety of rigid and semi-rigid containers:

Plastic tubs or cups

Glass, PET, or plastic jars

PET, rPET, PR, PP, PS, glass, or HDPE bottles

Food, beverage, powder, metal, or composite cans

Our closing technologies span a broad range of applications for liquid, semi-rigid, and powder applications. We can process a variety of closure types:

Double seam

Foil, aluminum, or plastic

Caps, TO, TOTO, PT, push-on, and screw

ROPP closure

IHS seal

Using our cutting-edge equipment locks in peak freshness and nutritional value, while ensuring the utmost food security.

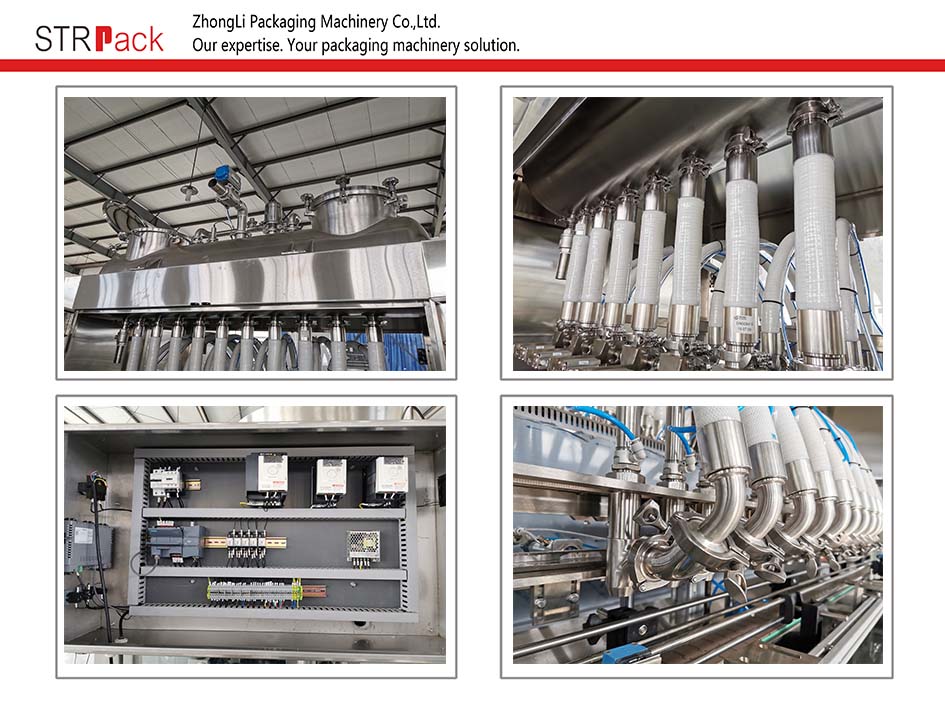

This Automatic Piston Type Sauce Filling Machine is piston type filling machine special made for filling cream or liquid foodstuff such as ketchup, sauce, honey, jam, peanut butter , mayonnaise, salad dressing etc.

Foodstuff standard product contact parts , and ok for high product temperature.

CIP product hopper , easy for cleaning.

The filling system is driven by servo motor which assure high filling accuracy ,also easy to set filling volume on the touch screen directly.

Features:

- Made by high quality 304 Stainless steel, it is durable.

- 316 stainless steel product contact parts is available for optional according to product features.

- Dosing system is driven by servo motor, it assure high filling accuracy.

- Liquid receive tray is available in case any dripping from filling nozzle.

- Air blow off filling nozzle is available for sticky product to avoid tail stringing on nozzle

- CIP Product hopper

- No bottle no fill.

- Linear structure which is flexible for varies bottle size.

- Controlled by PLC and operation through touch screen.

- No tooling needed to change over different size bottles.

- Quick-install connecting parts , it is easy to disassemble and clear machine.

Main Parameter:

|

Model |

Unit |

STRFS |

|||

|

Nozzle Number |

PCS |

6 |

8 |

10 |

12 |

|

Filling volume |

Ml |

100-1000ml/ 250-2500ml/500-5000ml |

|||

|

Production capacity |

Bottle/h |

1000-3000 pcs/Hour ( Depends on Filling volume) |

|||

|

Quantitative error |

% |

≤±1% |

|||

|

Voltage |

V |

380V/220V, 50Hz/60Hz |

|||

|

Power |

KW |

2.5 |

2.5 |

2.5 |

2.5 |

|

Air Pressure |

MPA |

0.6-0.8 |

|||

|

Air consumption |

M3/min |

0.8 |

1 |

1.2 |

1.2 |

After-sales Service:

(1) Under stable voltage, the machines' quality that we sold will be guaranteed for 2 year

(2) Long time technology will be supplied.

(3) We can dispatch our engineer to your side for installing and debugging machines. Engineer's round-trip tickets, accommodation, and your side traveling fee will be charged by you. Engineer's salary will be USD100.00/day/person.

We can also supply training process for your engineers who come to china, so you can fit and debug machines by yourself.

About Us:

--Focusing on Development, Packaging Industry Leader

--Keeping on Recruiting Talents and Innovation

--Advanced equipment, Guaranteed quality

For quick response please contact us by cellphone/WhatsApp:008617317720909