Specifying a capping machine is a little less complicated than a filling machine but like filling machines there are many ways to solve the same packaging problem depending on cap sizes, geometries, closure design, required production speed and plant environment. Part of this specification process also includes what type of sorter can be used based on the constraints above.

1. What is the size range of the caps?

Caps can range from very small e.g. 5mm diameter to a very large 120mm diameter. A size range this great is oftentimes impractical to work in one type of capping machine. A capping machine for very large caps may require a vertical placing device and then only a cap tightener to finish the process. Capping on extremely small caps may limit the type of capping machine choice because the bottles are too small to be handled any other system except a “monoblock” system that physically controls the bottle in a starwheel. The diameter size of these closures will also determine what kind of sorting device will be suitable. Very small caps may require small vibratory sorting systems while very large diameter caps may require large bulk elevator sorters.

2. What are the geometries of the caps?

The ratio of width to height of the closure constrains not only the cap sorting choices but also may determine what type of capping machine must be used for the application. Typical “flat caps” (where the width of the cap is always greater than the height of the cap) are fairly simple to sort, apply and tighten and will work on just about all types of capping machines. However, when the caps become square or taller than they are wide (i.e. tall caps), the options to sort the caps becomes limited to centrifugal and vibratory systems. Depending on the geometries of these caps, they may be capable of being stripped out of a cap chute or they may have to be picked and vertically placed onto the containers. This cap handling question will definitely determine whether or not an “in line” type capping machine will work or whether or not a chuck style vertical capper must be used. Some closures are not even caps at all; dropper tips, pumps and spray heads are typically economically prohibitive for automatic sorting and placing; they are usually hand placed and then tightened by an automatic tightener instead of a capping machine.

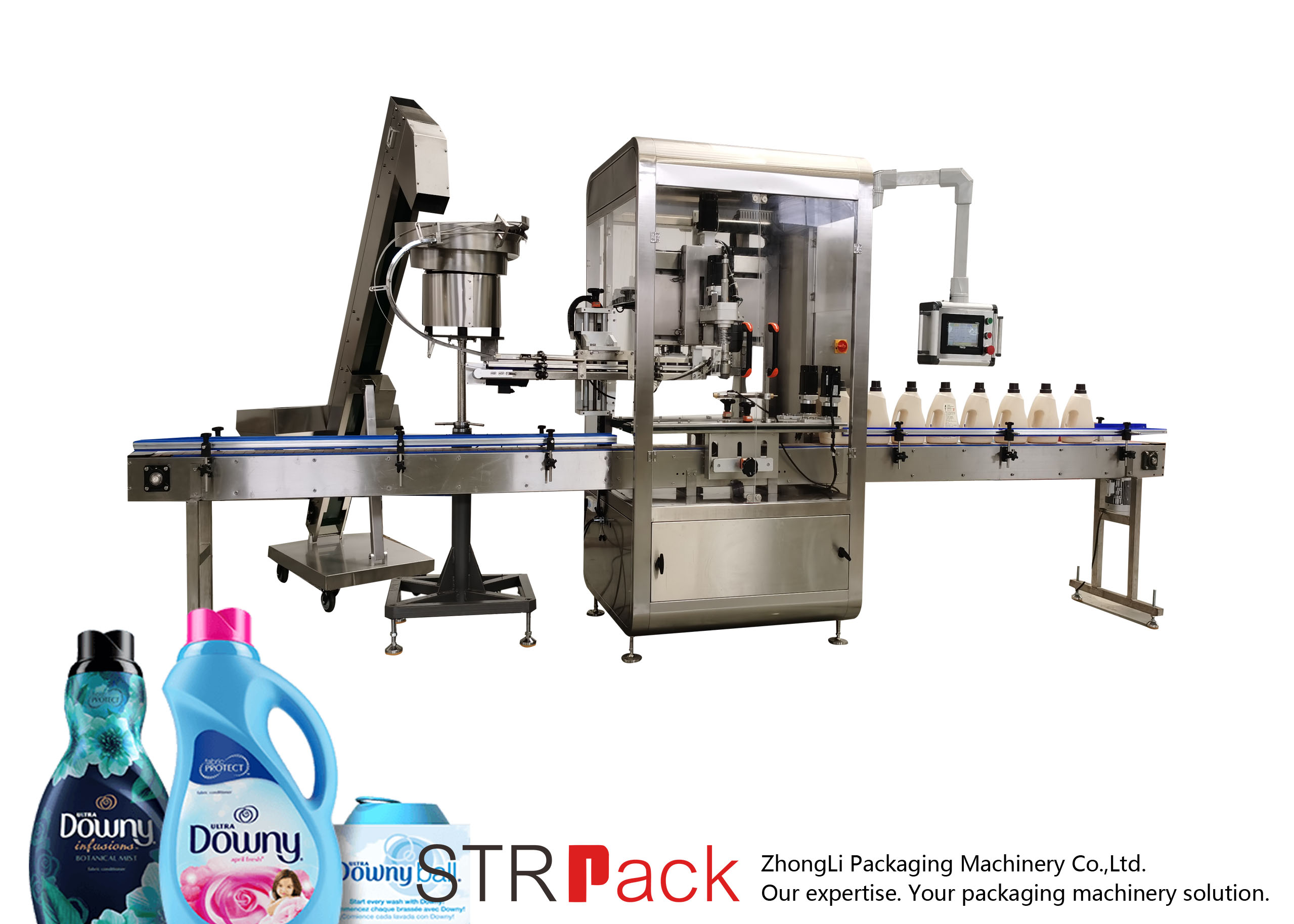

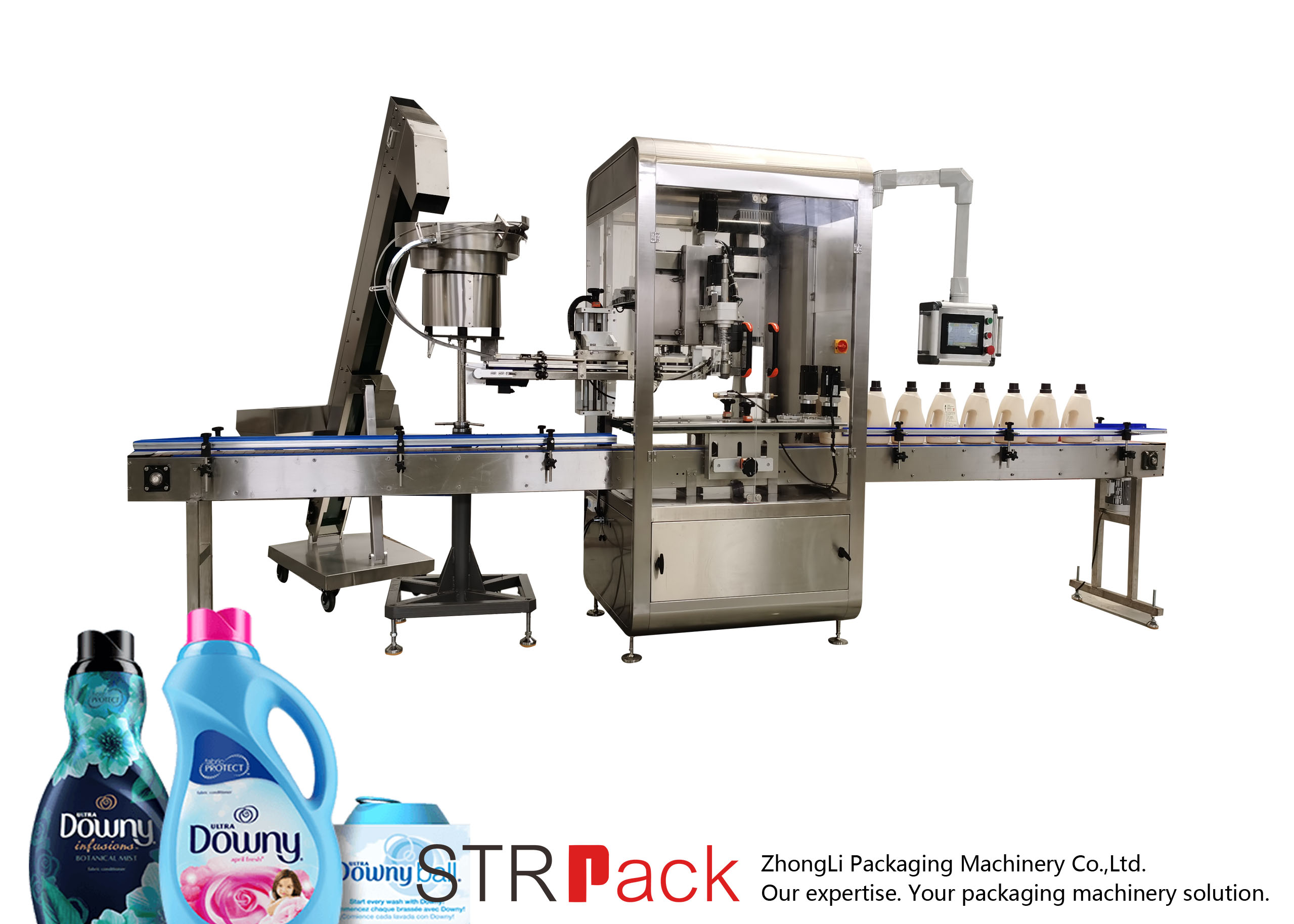

3. What is the closure design and the fit of the closure into or onto the chosen container?

Some threaded closures simply cannot be applied onto a container any other way than being “picked” into a a chuck type capping head and then vertically placed into or onto the container. A good example of this is a detergent pour spout cap. They are tall with a skirt that must fit into the mouth of the container before the threads can engage for tightening. Closures such as plugs, corks, stoppers and other fitments must also be sorted and vertically placed into the container. These machines are intermittent motion and run much slower than “inline” type of capping machines that are continuous motion. These vertical placement, intermittent machines are also more expensive than continuous motion cappers. In the case of very small plugs such as those used in pharmaceutical applications, an intermittent motion “monoblock” system must be used; the capital cost of these capping (plugging) systems can be prohibitive to smaller producers.

4. Will the capping machine be automatic or semi automatic or even manual?

The biggest constraint to productivity in a complete liquid filling operation is the capping process. To apply and tighten closures manually basis is extremely labor intensive with health risks to personnel such as carpal tunnel syndrome. Manually, capping speeds will never exceed 10 containers per minute (CPM) on a sustained basis. Semiautomatic systems can sustain higher rates at 15 to 20 CPM but with a commitment to a higher labor component. Any production rates higher than this will require at least an automatic tightener which can handle caps, pumps, and sprays as fast as they can be manually placed. From our practical experience in this matter, this rate is limited to approximately 30 to 40 containers per minute with several personnel involved. Fully automatic systems that both sort, place and tighten caps can reach speeds well in excess of 200 CPM depending on whether or not the cap styles are useable in a continuous motion machine. Caps and other closures that require intermittent motion machines will typically reach a maximum of 30 to 60 CPM on single and dual head chuck and plugger systems.